- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

ANCONN

- Model Number:

-

AC002

- Item Name:

-

10mm rubber stoppers oil proof

- Color:

-

black, clear or any other colors are available

- Material:

-

EPDM / NBR / Silicone / NR

- SIZE:

-

4, 6, 8, 10, 12, 14, 16, 18, 20, 25, 30, 50mm

- Usage:

-

seal the holes

- Shape:

-

T

- Function:

-

Waterproof, dustproof, airproof, oilproof

- Hardness:

-

30 ~90 Shore A

- stock:

-

we have them in stock

- Certification:

-

ROHS

Packaging & Delivery

- Selling Units:

- Single item

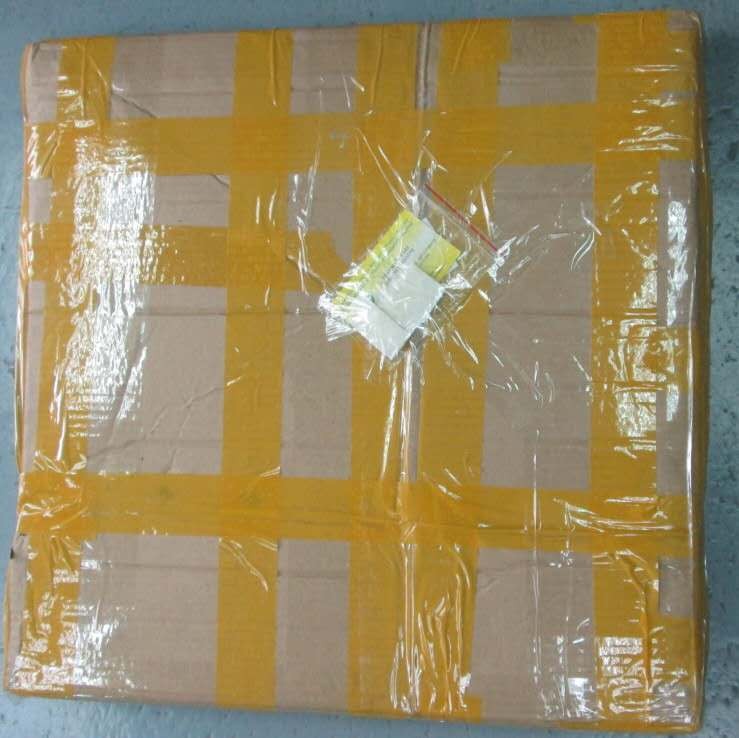

- Single package size:

- 35X30X28 cm

- Single gross weight:

- 0.01 kg

- Package Type:

- 2,000 pcs/bag, 3 bags/CTN. 18KGS/CTN

- Picture Example:

-

- Lead Time :

-

Quantity(Piece) 1 – 1000 >1000 Est. Time(days) 5 To be negotiated

silicone rubber NBR EPDM VMQ NR Rohs standard silicone caps Rohs silicone plugs tapered rubber stoppers medical rubber stopper 10mm rubber stoppers oil proof

What Is a Rubber Stopper? ( medical rubber stopper )

A rubber stopper is a small, tapered plug used to seal the openings of test tubes, flasks and other laboratory glassware.

Stoppers made of cork are also available for this purpose. However, rubber stoppers are preferable for applications

that require a tighter seal or a greater degree of chemical resistance.

Purpose ( medical rubber stopper )

The primary purpose of a rubber stopper is to prevent a gas or liquid from escaping its container

during a scientific experiment. Rubber stoppers can also prevent the contamination of samples

by protecting the contents of laboratory glassware from air. Last, the use of rubber stoppers allows

experimenters to shake or mix solutions without spilling them.

Shape ( medical rubber stopper )

The standard stopper is cylindrical in shape, with a tapered bottom end. Some rubber stoppers

contain one or two holes to allow the insertion of pipettes, tubing or test equipment (e.g., a thermometer).

Size ( medical rubber stopper )

Rubber stoppers typically range in diameter from size 000 (0.5 inches) to size 16 (5 inches) at the top.

The tapered bottom end ranges from five-

sixteenths to 3.5 inches. Smaller stoppers are appropriate for test tubes and similar glassware;

larger stoppers are appropriate for flasks and beakers.

Properties ( medical rubber stopper )

The main properties that make rubber suitable for use as a laboratory stopper are its elasticity,

chemical resistance and impermeability. Its elasticity allows it to form a tight seal against the inside

of the glassware. Its chemical resistance makes it safe for use with many corrosive and otherwise reactive

compounds. Its impermeability helps to prevent the escape of liquids and gases from the container.

| Part Name | Silicone rubber stoppers, plugs, caps |

| Service | OEM OR ODM |

| Part Material | Silicone or rubber (NR, NBR,SBR,BR,IR,CR,EPDM,IIR,(FKM),SIR,PU,ACM,CO,etc) |

| Material Hardness | Silicone about 20~80 Shore A; rubber about 30~90 Shore A |

| Size | Customized |

| Shape | Customized |

| Color | Customized according to Pantone colors |

| Appearance | as customer’s requirement |

| Drawings | 2D OR 3D acceptable |

| Temperature Resistance | -40~300 degree centigrade |

| Tolerance | 0.05mm |

| Technology | Hot pressing molding or injection Molding |

| Second Processing | Vulcanizing / Deburring / Silk-screen / Carving / printing |

| Quality control | internal QC control |

| Part Feature | 1.Oxidation , Chemical,oil, acid ,alkali , weather resistance |

| 2. colorful ,Anti-aging,good flexibility, good elasticity | |

| Food grade material | FDA or LFGB |

| MOQ: | Amount : More than USD 200/each part(depends on specific part) |

| Shipping ways | 1. By sea from Yantian port. 2. By express: DHL/UPS/FEDEX ,etc 3. By air |

| Package | Normally PE bag+carton or customized as customer’s request |

| Trade Term | Ex-works; FOB Shenzhen/Guangzhou ; CIF |

| Payment Term | Sample mold: 100% prepaid,MP Mould: 50% deposit by T/T in advance, balance 50% paid after samples approval |

| Goods: 50% deposit, 50% before shipment | |

| T/T, Western Union, PAYPAL | |

| Lead time | 5~10 days for making mold,7~15 days for mass production (depends on part structure ) |

| Specification | Confirm to ISO-9001 and ROHS Directive Compliant Green Products |

| Application field | 1. Electron components |

| 2. Medical equipment | |

| 3. Home appliance | |

| 4. Mechanical equipment | |

| 5. Office facilities | |

| 6. Aviation | |

| 7. Construction | |

| 8. Automobile |

-

4 6 8 10 12 15 16 18 20 solid silicone rubber t...

-

0.6 1 1.5 1.7 standard silicone oil seals VMQ o...

-

Silicone Rubber Pads For Crutch Stick Protectio...

-

silicone bungs panel hole plugs waterproof hole...

-

Pvc tube medical food grade silicone rubber fle...

-

1 1.5 2 2.5 4 inch High-quality high temperatur...